Biobank infrastructure

The TBB infrastructure is placed within the Institute of Pathology. Our equipment, personnel and standardized workflows are focused on the improvement and monitorization of pre-analytical variables that affect tissue quality.

SAmple processing

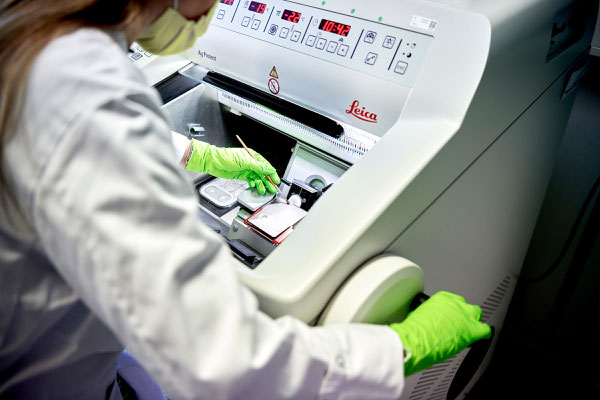

The tissues received for biobanking are processed by a group of expert pathologists supported by specialised technicians at the Clinical Pathology Division. Tumor and matching non-tumoral adjacent tissue is selected for storage or prospective projects, where is given directly to the researcher. A mirror piece of every given or stored sample is formalin fixed paraffin embedded (FFPE) in order to have representative material to make a quality control. The FFPE material is also available for further research projects.

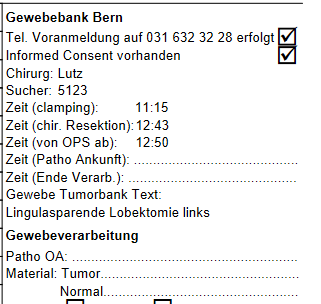

To assure the quality of the tissue at arrival, ischemia times are included in the patient report so they can be tracked from the clamping time or resection. The sample transportation from the operation room is automated and done in less than 2 minutes in most cases.

The cryotubes used for the storage and processing of the samples are of the highest quality, free of endotoxins, nucleases, heavy metals and animal contaminants. The 1D/2D triple pre-coding system allows unequalled sample traceability and reliability.

As part of our quality processes, every tissue designated for a project undergoes an exit quality control consisting on an HE staining from the frozen or from the mirror FFPE material. The HE is reviewed by an expert pathologist and a quality report is provided with the sample.

Additionally, TBB offers support to the biomedical research activities by facilitating compliance with best practice standards and regulatory requirements relating to ethical, legal and societal issues (ELSI).

Storage

Biobank samples are flash frozen to -70 °C in a pre-cooled Isopentane tank and transferred to a -80°C freezer for long-term storage. All the TBB freezers are equipped with the Central Monitoring System ELPRO® that takes and stores temperature data every 5 minutes and sends an alarm at a fixed temperature. This ensures the correct temperature maintenance and tracking for an optimal tissue quality preservation.