BioBank Infrastructure

The biobanking infrastructure of the Inselspital is located in the INO building. All equipment dedicated to pre-analytical processing (reception robot, centrifuges, primary tube transport system, pipetting robot, cryo-work benches, and bionbank sample elevator) are fully integrated into the 24/7 emergency and routine diagnostic Corelab of the ZLM on floor F. This set-up enables a full integration of the pre-analytical processes of the Corelab for clinical samples, and thus, diverse efficient and quality-assured workflows, which can be tailored specifically to the needs of individual clinical studies. Connected with a sample elevator, the automated -80°C and <-150°C storage systems are located one floor below in an access-controlled room especially equipped with all the infrastructure necessary for uninterruptable operation.

If you are interested into processing and/or storing of your samples in our biobank infrastructure, please see Biobank Services.

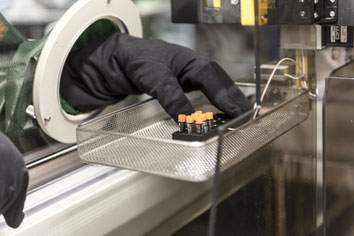

Cryotubes

For storage in the automated stores two sample tube types (0.3ml and 0.7ml nominal, 275ul and 525ul working volume) with external thread screw cap from FluidX® can be obtained directly form the BBS. These polypropylene tubes are of highest quality, can be flash-frozen, and are certified for a temperature as low as -196°C. The tubes are sterilized and free from DNase, RNase, DNA, and endotoxins. Each tube has a unique ID imprinted as a direct-laser etched 2D barcode on the base. In addition, a linear or 2D barcode and human readable ID is imprinted on the side of the tubes. Both tubes fit into standard 96 well format racks, which are used for many automatization Solutions.

automated aliquoting

A specific Microlab STAR Plus pipetting workstation has been developed by HAMILTON® especially for the BBS in order to achieve rapid sequential sample processing. In general, samples are aliquoted in less than 3 minutes and the system can be fed continuously with new samples. It consists of two linked robotic units, one for aliquoting various types of liquid samples from primary tubes into the standard cryotubes of the BBS, the other unit de-and re-caps and allocates the necessary cryo tubes. Key features of this system are displacement pipetting using disposable tips to avoid contamination, automated liquid-level recognition, and independent pipetting channels.

The aliquoting is barcode controlled and time points of aliquoting are tracked for each parent-child sample.

controlled freezing

For further sample processing, the BBS provides two ASKION C-line® work benches with a cryogenic working area at -170°C to -110°C and with an internal and an external barcode scanner. Both benches are directly connected to liquid nitrogen lines and are 24/7 operational. Due to the dry nitrogen atmosphere and the cryogenic temperatures inside the device (the workbenches contain a reservoir of liquid nitrogen at the bottom), the frozen samples can be sorted, repacked and/or temporarily stored.

The controlled and documented sample freezing can be performed on the basis of programmable freezing curves, including a "seeding" procedure for immediate crystallization. In principle, five independent small "elevators" move the samples in a predefined and temperature-monitored fashion along a measured temperature gradient in the workbench enabling a defined and reproducible freezing of various samples. All relevant curves are stored along with the sample information.

Following the freezing process the frozen sample can be moved without interrupting the cooling chain by using a nitrogen-cooled transport container into the -80°C and <-150°C storage Systems

Storage

Immediate controlled freezing and storing at <-150°C (vitrification temperature plus -20°C security margin) is currently considered to be the gold standard for the long-term preservation of biofluids from the cryobiological point of view (6). However, the technology for storing large sample collections at ultra-low temperatures is in its infancy and associated with high costs as robotics at these temperatures is an engineering challenge. Currently available biorepository systems are either capable of preserving ultra-low temperatures, but are not suitable for large-scale sample throughput or vice versa. Additionally, many known and established biomarkers are stable at -80°C for reasonable storage periods. At present, the focus for the majority of the samples is therefore on storing biobank samples at -80°C as the market provides technically reliable systems for the automated storage of samples at this temperature, and because it is considered the most cost effective option for research based on biobank samples today (7).

While it has been shown that liquid samples remain stable at a storage temperature of -80°C with regard to most standard clinical laboratory biomarkers, it has also been shown, that some proteins may degrade rapidly in biospecimens stored at this temperature (8, 9), indicating that -80°C is probably not sufficient for omics-based (e.g. proteo-/metabolomics) research. Along with the ever-increasing sensitivity of diagnostic platforms (e.g. mass spectrometry), this problem will become more prominent in future.

Storage at -80°C

The automated sample storage (HAMILTON® BIOS) system of the BBS has been evaluated in a public tender based on stringent performance characteristics, such as temperature stability, security, sample tracking, flexibility, energy consumption, efficient storage, and reliability required for biobanking of clinical samples.

In its present configuration, the -80°C BIOS can store ca. 2 million cryotubes on standard 96-well racks. The temperature stability for maximum sample integrity is ensured in automated lid-covered chest freezer compartments. A -80°C tube picker/sorter is a key component of this system that has been optimized to minimize warming events during internal processing.

In the center of the front a blue-lighted reception area is displayed, , the automated tube picker is located at the front right corner, and the robotic arm lifting the rack trays is positioned over the second chest row.

Storage at <-150°C

With the ASKION - C-line® system the BBS offers storage capacity at <-150°C. This is one of the first systems enabling fully-automated sample introduction, sorting, and sample removal at such low temperatures. Samples are stored in stainless steel barrels in the gas phase of liquid nitrogen and the sample handling takes place at <-100°C with a fully-automated picker. The picking process is so fast, that the deep-frozen samples do not reach -130°C during sample handling. In total three ASKION - C-line® systems provide storage capacity for more than 100’000 cryotubes.

The systems are interconnected by an external rail system, which transports the nitrogen-cooled sample containers for automated sample introduction and sample removal without interrupting the cooling chain.

Referecses

6. Benson, E., Betson, F., Fuller, B. J., Harding, K. & Kofanova, O.2013. Translating cryobiology principles into trans-disciplinary storage guidelines for biorepositories and biobanks: a concept paper. Cryo Letters 34, 277–312.

7. Elliott, P., Peakman, T. C.UK Biobank. 2008. The UK Biobank sample handling and storage protocol for the collection, processing and archiving of human blood and urine. Int J Epidemiol 37, 234–244.

8. Tworoger, S. S. & Hankinson, S. E. 2006. Collection, processing, and storage of biological samples in epidemiologic studies: sex hormones, carotenoids, inflammatory markers, and proteomics as examples. Cancer Epidemiol Biomarkers Prev 15, 1578–1581.

9. Rai, A. J. et al.2005. HUPO Plasma Proteome Project specimen collection and handling: towards the standardization of parameters for plasma proteome samples. Proteomics 5, 3262–3277.